Construction Risk Management: How to Reduce Top Construction Risks

How to Manage Risk in Your Construction Project

According to The Construction Industry Institute, there are about 107 construction risks you should consider when managing a project. Before you start panicking about the 90 plus risks on the list you’re probably not completely aware of at this moment, let’s take a step back. While comprehensive, a list that long isn’t quite actionable because it contains many things you can’t control such as force majeure or acts of god.

In most projects, internal resources are stretched thin and project managers struggle to consistently deliver the necessary performance and control assessments. Just to keep projects moving, many companies aim to control and manage construction risks within reasonable limit only—still leaving much open to ambiguity. Regardless, a solid risk management strategy is critical to the security of your company and project. So, how do you know where to appropriately invest your time and resources in order to minimize major construction risks and control what often feels uncontrollable?

What is Construction Risk Management?

Construction Risk Management is defined as a process or system to identify and reduce various risks within a construction project.

Given how difficult it is to control risk, construction software is one solution that can help to manage multiple large risks if implemented throughout the course of the project. With the right program and team, formulating a risk-based operational excellence program can help you better manage the entire end-to-end project lifecycle. To help you prioritize your risk assessment, we identified the main classifications of risks, as well as the top 6 risks that you can actually control with the right construction software.

Key Takeaways:

- For every construction project, there are around 107 risks to consider, according to The Construction Industry Institute.

- Using construction software may be a solution that helps you manage large risks when used throughout the project. Risks are classified into categories including finance, schedule, and design.

- Risk mitigation in project management helps prevent delays and rework, helping project managers provide stakeholders with timely access to reports, data, and documents while improving transparency and producing a higher quality of work.

- The six top risks to address include labor issues, safety hazards, coordination hurdles, poor documentation, inconsistent reporting and errors, and disputes.

- It’s possible to reduce risks with software and a solid risk-management program.

Jump to Section:

- What is Construction Risk Management?

- 3 Primary Classifications of Construction Risks

- Why is Risk Management in Construction Important?

- Risk 1 – Labor Issues

- Risk 2 – Safety Hazards

- Risk 3 – Coordination Hurdles

- Risk 4 – Poor Documentation

- Risk 5 – Inconsistent Reporting and Errors

- Risk 6 – Disputes

- Top Technology to Reduce Construction Risk

- Control What You Can: Reduce Construction Risks With Software

3 Primary Classifications of Construction Risks

To really understand how software can help control a project’s risk, it’s first important to understand the major types of risks. Generally, risks on construction sites fall under one of three categories: finance, schedule, and design.

1. Finance

Although exceeding budget on projects has become an industry-wide norm, finance issues are primarily a result of bad planning and coordination. We all know how megaprojects can easily go millions and even billions over budget. Regardless, if a project experiences just a budget excess of a small percentage, this could affect not only the managing company’s future liquidity, but you risk not being able to pay workers for their hard work and ultimately see the project in a standstill.

2. Schedule

In the construction industry, the phrase “time is money” can mean a whole lot of it. Undeniably, poor scheduling can have a devastating impact on a budget. Just one small miscommunication or mistake in a report could set your schedule back by days, weeks or months due to needs like rework and rebooking subcontractors, not to mention creating large cost overruns. Even a small delay can have project wide impacts that can completely change the original project schedule. This means the project team must change their master game plan which inevitably leads to more miscommunications or mistakes.

3. Design

Design management during construction is a growing risk that must be carefully managed. When push comes to shove, a project team may decide to accept an unfinished design that is “good enough” to build just so construction can start on time. The project team will then back-manage this risk by working to get the design caught up during construction. This scenario is increasingly more common in today’s market where speed to start construction is a primary request from owners. Often, construction risks related to design can be better managed starting in the preconstruction planning phase when the owner, designers, and contractors can align more closely.

Why is Risk Management in Construction Important?

Understanding the wide variety of risks in the major areas of the construction process can help explain why it’s important to closely manage it throughout the course of the project. More specifically, ineffective risk assurance and related decision-making often results in carryover legacy issues which burden the project for the remainder of its lifecycle. Without proper risk assessment and control, project officers will find themselves in a position where they are relying on those who manage the risks to report on them, creating a cycle of delays and rework.

Furthermore, construction projects tend to have extremely complex stakeholder structures with multiple relationships that come into play. For instance, governing bodies (board, steering committee, audit committee, etc.) all have appropriate transparency and insight into the project’s risks. As a result, project officers may fear they’re not getting the full story from their project teams and that bad news may not arrive in time to fully address the risks—pushing back project schedules and creating massive cost overruns.

The good news is that, through software, owners and project managers can actually mitigate the cycle of delay and rework and provide a higher level of project visibility to stakeholders by allowing for:

- Timely access to data, documents and reports

- Enhanced transparency

- Higher quality of work and integrity

To help you better understand how software can extensively enhance your construction risk management strategy, we highlighted top construction risks with the greatest potential to impact project cost, schedule, and design performance. With these key takeaways in mind, you can start to allocate resources in a more efficient and cost-effective manner, to manage the highest priority risks early in the project lifecycle.

Is your organization prepared for the year ahead? Take a critical look at your approach to risk and helpful construction benchmarks in this report:

Risk 1 – Labor Issues

Labor Shortage

Although demand for construction projects remains at an all time high, finding the right people to complete projects is a major pain point for today’s construction professionals.

According to a recent survey of contractors by Autodesk in partnership with the Associated General Contractors (AGC) of America, 80% are struggling to hire skilled workers due to an ongoing skilled labor shortage.

At this time, the labor shortage is the most obvious risk to construction projects. The fact is, even with the best preconstruction planning and designs in the world, if you don’t have the enough staff to actually execute the work, your project is doomed for significant delays from the start. Alternatively, if you lower your hiring standards and just try to fill in the shortage with inexperienced workers, you also put the state of your project, as well as staff, on a dangerous path. Therefore, how is it possible to attract and retain more workers with this industry wide dilemma?

Although the industry needs to address the larger issue of the labor shortage including a commitment to better recruitment and training, these tactics won’t solve shortage in the short term The good news is that technology can help you fill the gap now and attract more high-skilled employees.

In particular, implementing mobile construction software will provide you with an advantage to attract younger employees like Millennials who are already digital nomads and looking to further advance their technological skills on the job. On the other hand, if you’re worried that your most experienced employees, Baby Boomers, will be overwhelmed by new software, a knowledge-sharing program could be useful. Most likely, older employees are among your greatest workforce asset due to their comprehensive knowledge of the industry and projects, but as retirement looms, you risk losing that knowledge resource. To teach Baby Boomers skills in the short term, Millennials can show them the ropes to new tech, while your more tenured employees can instill their breadth of knowledge to their younger counterparts. In turn, productivity and collaboration will not only improve, but you provide junior staff with a unique internal training program that could increase job satisfaction and retention.

Labor Productivity

Whether labor shortage is an issue for you, you are probably faced with another workforce issue impacting your project’s overall risk—productivity. Just to put things in perspective, according to one study, the productivity of two groups of workers doing identical jobs on the same site and at the same time can vary by up to 50%. This gap in productivity was found to vary by 500% when the work was done on two different construction sites. Even with a full roster of workers and subs, can you really tell if your staff is making the most of their time on your dollar?

Technology can not only help to attract and retain the best employees, but it can also be used to improve the overall productivity of the workers already on your payroll. This way, you can justify your costs and decide which subs to reach out to again for your next project based on how productive they are. With the right software, you can actually quantify your workforce’s productivity and measure it over time, helping to make better hiring decisions and reduce the risk of future projects.

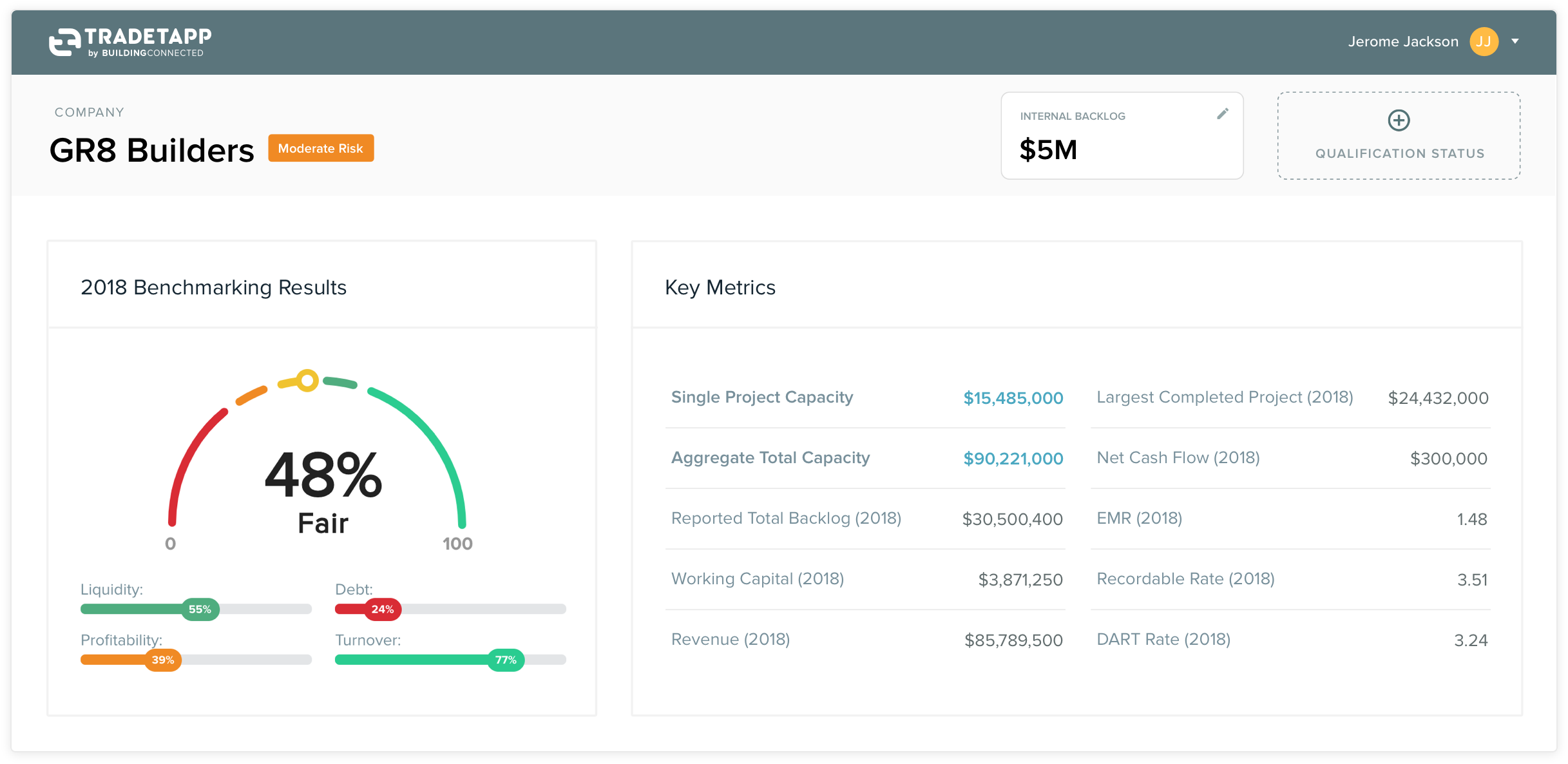

Labor Quality

Hiring the wrong subcontractors is a construction risk that many general contractors seek to avoid. However, the start of a project can often feel like a blind audition, with very real impacts, like lengthy project delays, high budget overruns and even litigation, if the wrong crew is selected. Using qualification software is one to reduce the risk of hiring the wrong team. By using software like BuildingConnected, contractors can easily assess a subs financial situation, safety record and insurance. While there is always an element of risk when it comes to selecting subcontractors, using an industry-recognized qualification platform helps to put more control back in their hands.

Risk 2 – Safety Hazards

Unsafe work conditions on construction sites are another major risk related to your workforce. We, of course, all want to make jobsites safer, first for the well-being of our employees and secondly to ensure faulty safety procedures don’t hinder a project’s ability to move forward. With today’s modern and diverse workforce, language obstacles and other miscommunications can have a negative impact on safety. Notably, due to language barriers, Hispanic workers face an increased risk of injury or death on construction sites. Although these workers may be highly skilled, if information or an issue gets lost because it wasn’t fully translated in the moment, you put your project, and possibly company, on the line.

Once again, an industry-wide commitment to language training and multilingual support materials will help alleviate the problem in the long term, but it won’t help to fix the situation immediately threatening your workforce and projects. Implementing construction productivity software programs that have dual Spanish and English support, makes the jobsite safer by allowing for language localization and real-time mass communications. When there is one source of truth on the jobsite, everyone is up-to-date and you don’t have to worry about anyone missing important safety updates.

Other software is taking a predictive approach to managing construction safety. Learn more about how AI and machine learning are transforming construction (and reducing risk) in our video below:

Risk 3 – Coordination Hurdles

Miscommunications can naturally occur even when the whole team speaks just one language. From misalignment on design documents to neglecting to see work changes in time, there are countless ways where communication can push back schedules and risk the project’s success. For example, if a work order for plumbing arises and is not communicated in time, a drywall sub might move ahead with work on that section because it was in the original scheduled plans. Beyond a demolition and rework, this simple mix-up will most likely lead to concurrent schedule delays and potential cost overruns. As you can see, poor communication can be a major hurdle to risk management, leading to wasted materials, high turnaround time for RFIs, and costly reworks if everyone is not on the same page.

Software helps alleviate construction risks due to miscommunication by simply putting everyone back in alignment. When plans, markups, RFIs, and more can be found in one cloud-based platform, updates can be pushed effortlessly to your whole staff in real-time. As a result, your team now has the right data to make informed decisions, reducing the risk of going over budget and disrupting your timeline.

Risk 4 – Poor Documentation

Construction projects, especially megaprojects, require hundreds, if not thousands, of documents which can be a headache to manage in a paper-based system. In fact, shockingly 40% of construction companies are still using paper plans on the job. From managing the preconstruction process, moving forward the construction phase, to completing a successful project closeout, your team will have to constantly access documents including those out of context docs that can be difficult to locate. Finding documents manually can have an enormous drain on your time, and even more difficult is to put that information to work in a timely manner, leaving your project open to the risk of potential schedule delays.

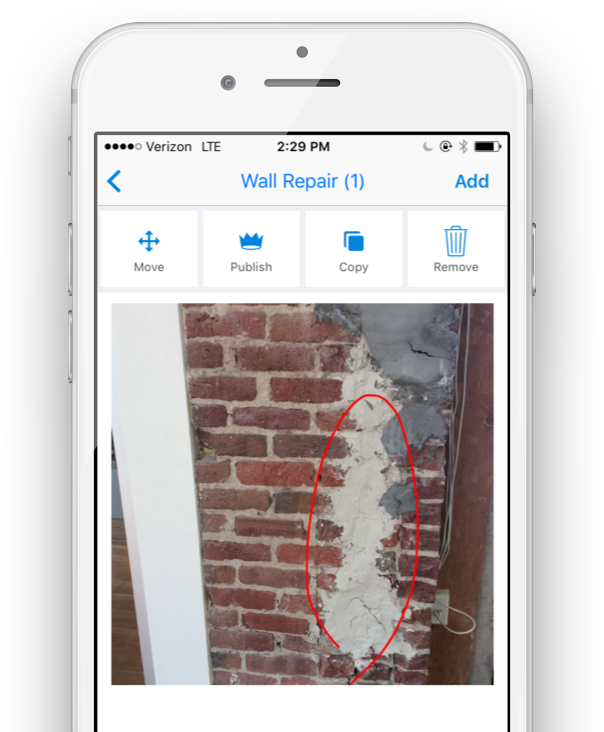

Risk 5 – Inconsistent Reporting and Errors

If your current manual report processes leave room for delays and error, you greatly risk your project timeline and budget. As an example, if you’re out on the field and notice an area with damaged electrical wiring, in a paper-based system you will have to wait until you’re back in the office to record what you saw to resolve the issue. This could delay critical information for hours or even days later and you risk recording misremembered or outdated information. With mobile construction software that includes options for timely field reporting, you can check to see if the issue has already been reported, and if not, submit your report immediately to ensure timelines are intact.

Learn more:

Another added benefit of submitting field reports through mobile software is the option to automate reports, reducing the risk of human error. By filling out a template form on a tablet or smartphone, you spend less time creating reports and more time moving towards project closeout. Furthermore, there are software solutions that allow you to go really deep with reporting and assignments. Good software will let you report the problem in a timely manner, but great programs will allow for rich media and data like photos, videos, and reference documents to be added as an extra level to enhance how you share information.

Risk 6 – Disputes

By far, construction is one of the most dispute-ridden industries. According to the 2022 Arcadis Global Construction Disputes Report, the global average value of disputes was $52.6 million and the length was 15.4 months. All construction companies aim to avoid litigation at almost all cost due to the crippling financial and schedule hits they cause. Disputes are caused for numerous reasons but primary causes include, poor contract administration, payment issues, errors and omission in designs and poor quality work.

The best way to reduce the risk of disputes is to follow a similar approach to the one proposed in Risk 4, document everything. Building information modeling (BIM) can substantially improve documentation processes from the beginning, especially if the technology is implemented throughout the constru

ction lifecycle. With a full set of data and improved visualizations, BIM software can help provide the clarity to proactive avoid rework and disputes as well as provide the enhanced documentation needed to expedite litigation, in a worse case scenario.

Top Tech to Reduce Construction Risk

If you’re among this one-third still relying on outdated systems, it’s time to adopt the technology to streamline construction risk management and improve operations and profit in the process. Here’s a look at 10 tech tools that can help get you there:

1. Mobile Technology

If you’re not using technology made for mobile out in the field, there’s no better time than the present. That’s because mobile-first technology does more than streamline communication and collect data; it can significantly reduce risk—and it does this by making data more accessible to team leaders and project team members.

By using the right mobile technology, teams can access documents and other information that they need within seconds. They can also update any documents or other information on the go as they work. This, in turn, helps lead to better jobsite accuracy and better overall decision making on project sites. As a bonus, using mobile technology on the jobsite can even help reduce insurance premiums, and if this occurs, it’s a critical indicator that overall risk has been reduced. As a bonus, reducing insurance premiums will only go to benefit your bottom line and overall profitability, as one of your vital overhead costs is trimmed.

2. Cloud-Based Platform

Mobile technology is one thing, the cloud is another—and you can’t go mobile on project sites without also being in the cloud. Cloud-based technologies allow users to make changes on the fly in real-time, as documents and information are stored in one spot that all users have immediate access to.

Here’s a look at some of the benefits of cloud technology and how it can reduce risk on your work site:

- Visibility: The entire team, and not just one or two individuals, have access to plans and other documents. They can make and see updates occur as they happen.

- Security: It’s secure, so your documents are always protected.

- Accessibility: As long as you can connect to the server or get an Internet signal, the cloud is there for you. Cloud technology is ideal for project teams working in remote or hard-to-reach locations.

And finally, when it comes to construction risk management on project sites, a cloud-base platform is especially helpful because it permits easy documentation. Meaning potential construction disputes and even litigation can be avoided by simply ensuring that information is being documented properly.

3. BIM Models in the Field

Building Information Modeling (BIM) has already left its mark on the design of projects, but bringing BIM models to mobile devices is still largely a work in progress at many construction companies. Think about it this way: If BIM software isn’t easy to access in the field, then it can be difficult for teams to have the information they need to build correctly. The lack of this rich information can potentially lead to errors on the job, which can extend deadlines and blow up a budget.

Bringing BIM software to mobile devices can go a long way toward streamlining operations on the jobsite, eliminating rework and keeping projects on time and budget. Mobile-friendly BIM software, such as Autodesk Build, can help teams build more effectively and efficiently.

4. Collaboration Tools to Manage Documentation and Communications

Don’t underestimate the power of good, transparent communication when it comes to risk management. We’d suggest investing in some good collaboration software in your company, as these tools allow teams to come together to connect on plans, information and workflow to reduce many labor risks. These tools also allow for increased visibility for stakeholders to improve accountability and, ultimately, productivity.

5. Task and Schedule Tracking

Getting behind schedule or off track is never ideal with any project, especially when you consider how it can open up companies to significant labor and financial issues. That’s why we strongly recommend investing in apps and software designed to aid collaboration and maintain tasks and project schedules. Not only does doing so help construction risk management, but it also helps teams make better decisions about how to carry out certain parts of the project, especially if they need help getting back on schedule. What’s more, is these tools also aid in improving accountability.

6. Automation Tools

Conventional manual data entry isn’t just time-consuming and tedious—it also leaves project teams open to significant risk from human error. It doesn’t matter how detail-oriented your staff is or how many times you cross your “t’s” and dot your “i’s,” mistakes are still bound to happen when data is entered in this manner. It’s why you should never rely on manual data entry, as just one seemingly minor mistake could lead to a slew of problems in the future.

The good news is there are a variety of quality construction tools to help automate operations and support data-driven jobs. Automation can also help improve workflow and lead to higher levels of efficiency and effectiveness.

7. IoT and Wearables

We’re sure you’ve heard the Internet of Things (IoT) before, but have you embraced it? The same goes for wearable technology and sensors. According to the Dodge and Data Report, nearly 75% of all construction workers think that IoT technologies, wearables and sensors can help improve occupational risks. So has your company invested in them yet? While there’s an upfront cost associated with these technologies, the savings you can experience has the potential to be significant.

For instance, wearables work to collect key data from the workers on a project site, relaying this essential information to team leaders to ensure proper protocol is being followed, and that workers are physically healthy on site. If any irregularity is detected, team leaders are immediately notified and can take prompt action to ensure a safe jobsite. Gilbane is an excellent case study on the value of this technology, which you can read more about here.

8. AI and Machine Learning

Can you predict the future of project risk? Being proactive—and not reactive—is a big part of construction risk management, and artificial intelligence (AI) and machine learning can help identify jobsite risks that humans might not be able to assess. While the construction industry has yet to see the technological advances of many other industries, these advances are coming, and AI and machine learning are two that are certainly going to shape the future of the industry.

9. Subcontractor Prequalification

With the current shortage of trades workers and the variety of subcontractors able to help on a project, it can be a challenge to get the right workers on a jobsite. But it’s imperative that the right steps are followed so that only qualified workers are performing tasks on site. One thing you should absolutely be doing as it pertains to subcontractors is prequalifying them before hiring. This essentially means you’re “interviewing” them before bringing them on site, enabling you to weed out the unqualified. One great solution to help do this is subcontractor qualification software.

We probably don’t need to tell you this, but we will anyway: Taking the right steps to bring on the right subcontractors will lead to a better quality of work and a safer jobsite. Make sure you’re doing your homework in this area, or else it could cost you big time—in reputation, budget, and schedule.

10. A Connected Tech Ecosystem

So you’re ready to begin the job, and all of your software tools are in place. This might sound like a weird question, but are your software tools talking to one another? Yes, talking to one another. Don’t silo your data on different platforms, as this can create more confusion than unison. That’s the big value of a program like Autodesk Construction Cloud Connect (ACC Connect), as it can help you connect your data dots to ensure a more efficient and safe jobsite.

Control What You Can: Reduce Construction Risks With Software

Hopefully, you have noticed that all six of these construction risks have one thing in common: uncertainty. When you leave projects open to chance, unforeseen circumstances could dramatically impact how and when your project will be built, not to mention cause unnecessary stress for you and your workforce. There are already so many uncertainties in construction that are out of your control; why risk not controlling the ones you can? By integrating construction software into your project at the beginning, you’re choosing not to leave the controllable to chance. With the help of technology to create a more soundproof risk-management program, you will positively impact the success of your project, your staff and personal well-being, and of course, overall profit margin.

Bonus: If you’re looking for more insight into risk in construction, take a look at our 2023 Construction Trends report.

The post Construction Risk Management: How to Reduce Top Construction Risks appeared first on Digital Builder.